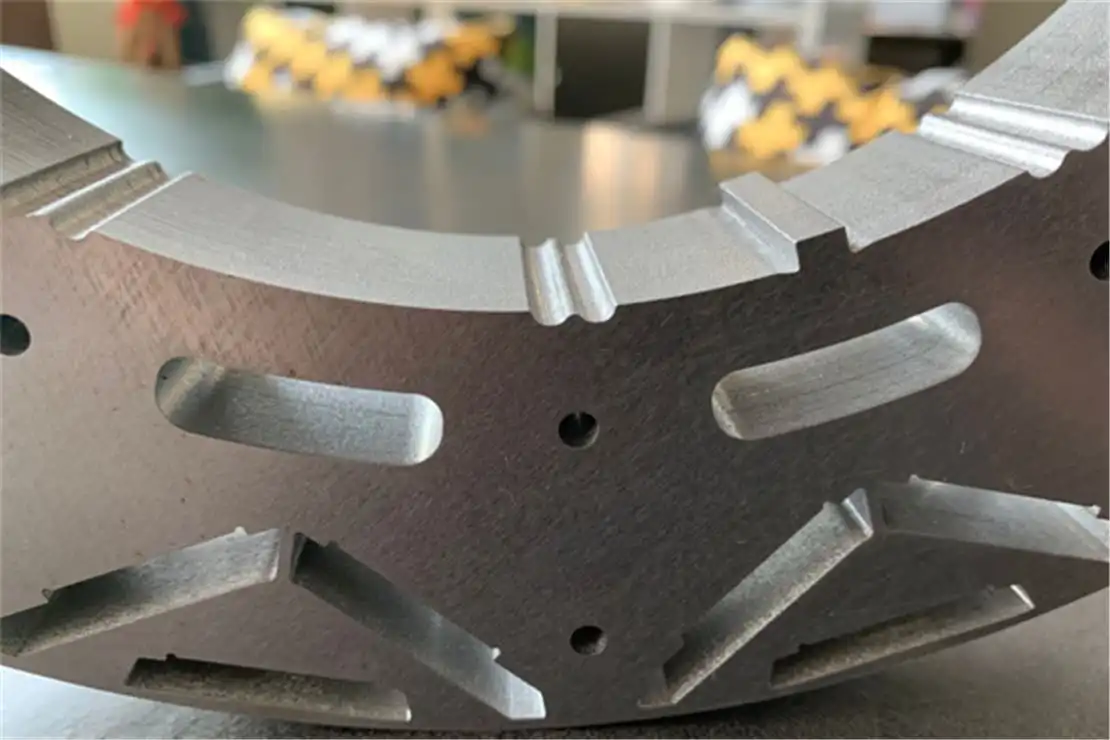

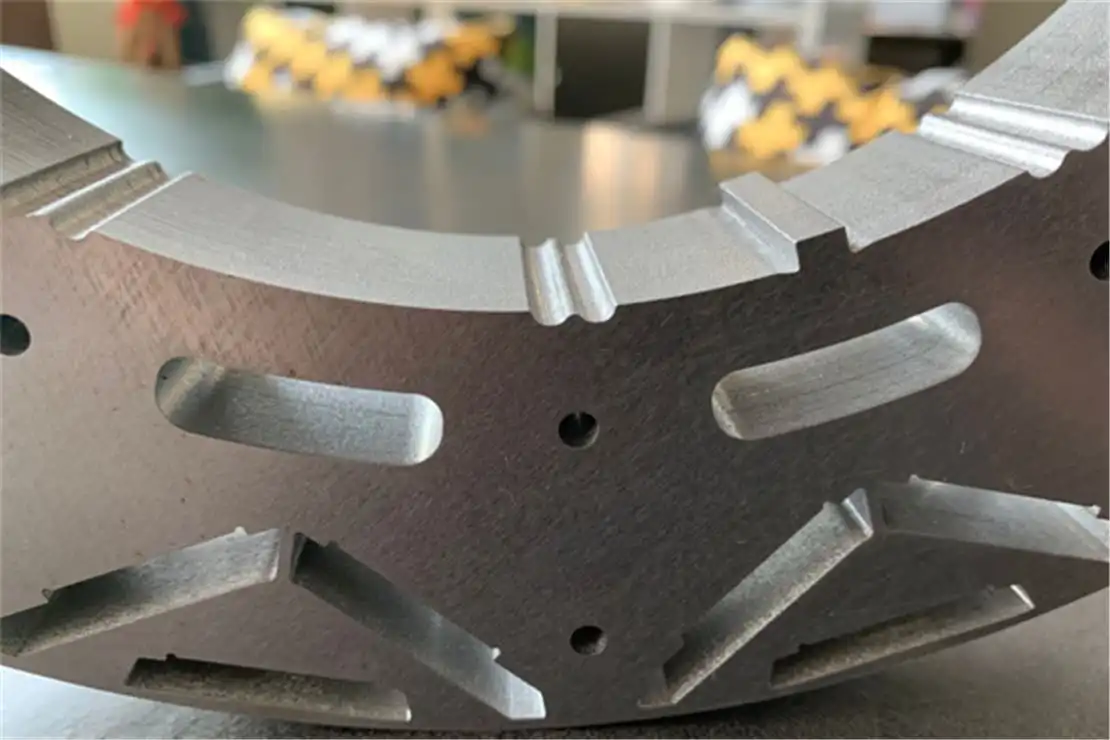

The stator and rotor cores of electrical machinery are manufactured using thin laminations stacked together in order to minimize eddy current losses. There are several ways to join these laminations, and the most efficient way is to use Backlack.

Compared to interlocking and welding, bonding has not short cuts between the single sheets. Better magnetical properties and lower losses are the result.

The single sheets are glued together tightly which reduces vibration and noise. A good approach to address the higher requirements.

The full area bonding improves thermal conductivity within the stack because bonding varnish/Backlack has a better thermal conductivity than the air we have from interlocking or welding.